Easy and accessible with assetMaster

Easy for maintenance technician, both online and offline.

Become 100% mobil with

assetMaster

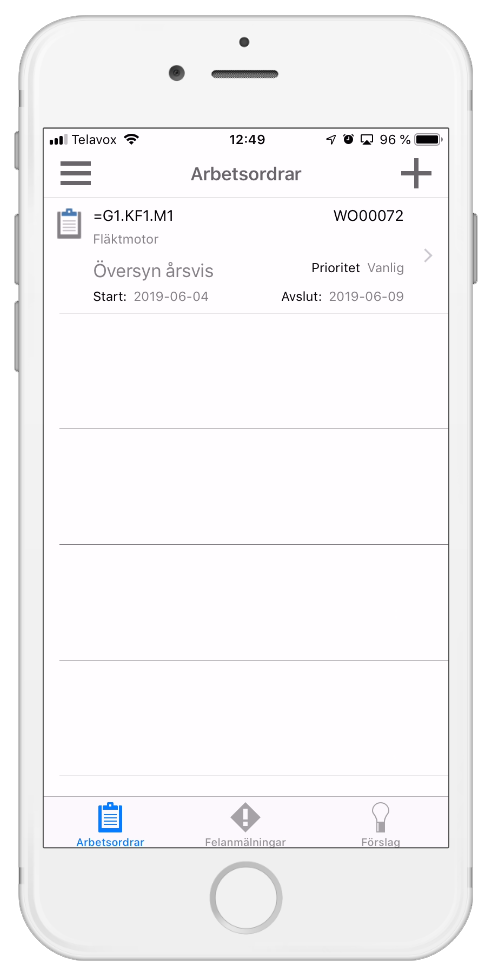

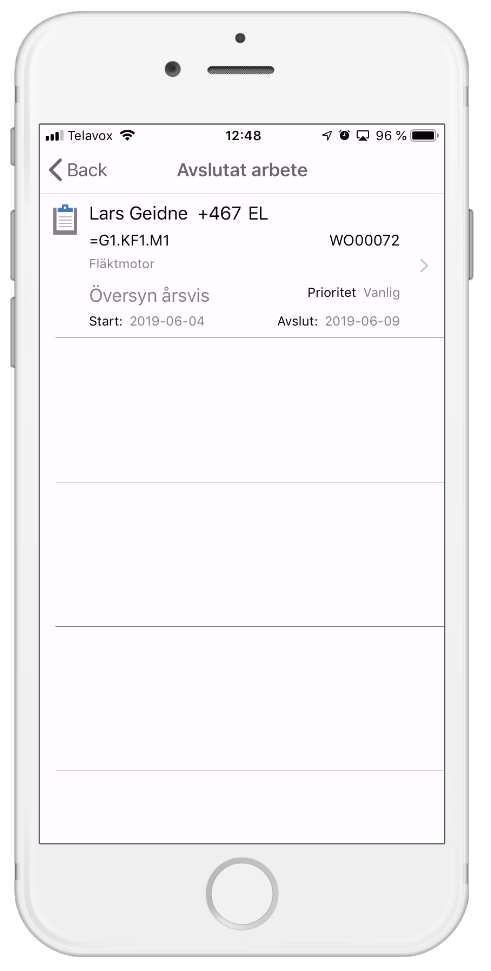

The assetMaster app gets a new look and new features. The app works whether you are online or offline to ensure that you can always do your jobs regardless of connection. assetMaster is available for all mobile operating systems.

News:

• Error report with review and approve / reject work orders.

(e.g.) group managers or project managers can review, leave comments and grade the work before it is completed and approved. If the work order needs be supplemented or redone, you can easily send it back to the provider. Both in the asset Master app and the desktop version.

• Picklist

To simplify the planning of work orders, you can now assign a work order to a department or to an unspecific resource. Available resources get the work order in a pick list where they can easily choose which work orders they want to pick.

Article, Inventory and Working permit

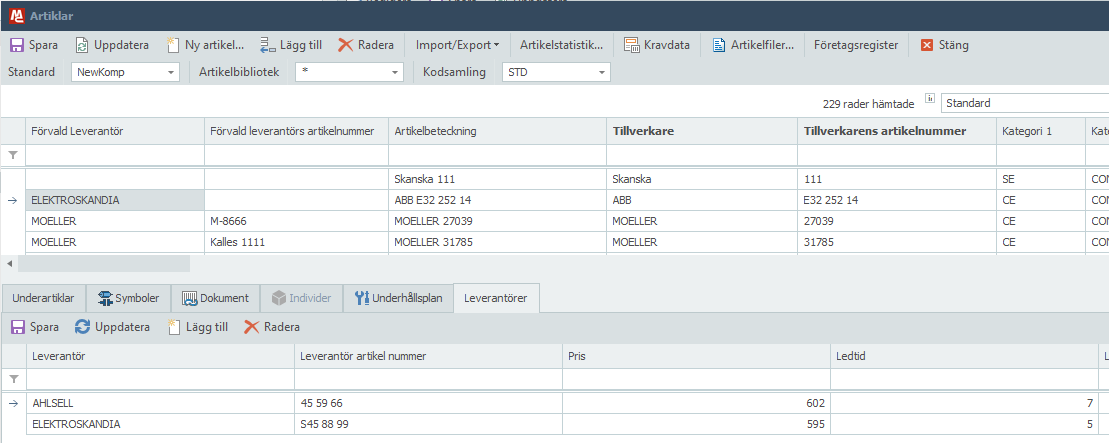

Article management

The article management has been updated and restructured. It starts with a business register where companies are managed. All are companies suppliers and manufacturers.

The article have a relation to the Manufacturer but can have several suppliers.

Each supplier can have different lead time for the supply and different prices of the same article.

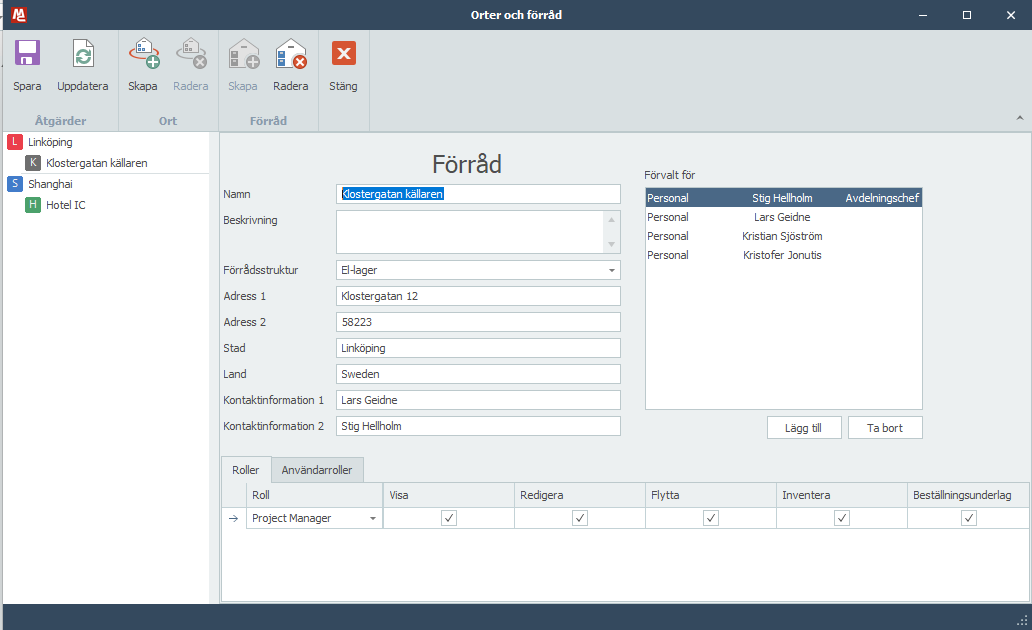

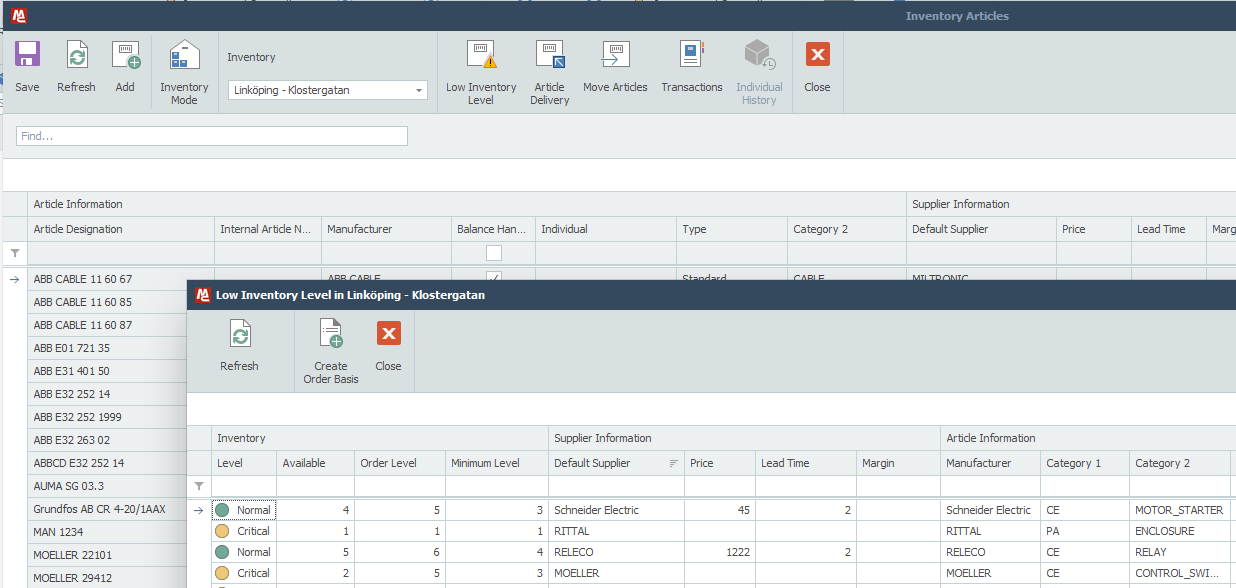

Inventory management

Master concept is now covering inventory management through out the operation and supply chain.

An inventory can be a physical room or a service car. All transactions are logged and data can be tracked to whom and why someone access the inventory and take out equipment and spare parts from the inventory.

The inventory can have a structure where different Individuals and pare parts have their positions in the inventory.

Smart functions in inventory management

With Master concepts mobile APP the user collects items from the inventory within the work order.

Smart traceability logg continuously tracks changes in the inventory.

100 % digital Risk assessments, Disconnecting & Connection and OH&S Management

All planning before the work order is executed is essential. It’s not just who does it and when but the work must be safe for the person who execute the work as well as environmental aspects.

Master concept have a digital platform where the overall OH&S Management of risk assessments are done. Both by the APP but also that all follow the same procedures. Support that the safety check has done on site and maybe by more than one person with strict authentication requirements.

Disconnecting electrical and mechanical equipment before work can be executed is also essential and a requirement. To many accidents occur where there is pressure still in a pipe system or hazardous chemical gas and liquids in pipes. Follow standards for highest safety either ISO standards or local such as electrical safety assessments.

Simplicity creates efficiency

With assetMaster, all maintenance work becomes simple and accessible. You can easily report work on any platform. Perfect for large user groups.

Report work

Create fault reports and improvement suggestions

Retrieve protocol/checklist

List my work order

Show detailed work order

Get 100% control on

Maintenance

Master concept’s new maintenance module provides several new features to simplify your maintenance work. With checklists you can easily tick off work steps or fill in work order with scanned measurements. New calendar function makes it easier and precisely to schedule preventive maintenance activity. To simplify the planning of work orders, users can now assign work orders to one department or to an unspecific resource. Available resources get work orders in a pick list where they can easily choose freely.

AssetMaster review completed work. The group or project managers can review, leave comments and evaluate the work before it’s completed and approved. If work order needs be supplemented or redone, group managers can easily send it back to the performer by Asset Master app or the desktop version.

Different Workorder type

It’s now possible to add different types of Workorder. A workorder generated from a fault report is probably a corrective maintenance type but a workorder generated on scheduled basis is a preventive type. Good for statistics and different preparation methods.

Maintenance based on the equipments lifespan

Master of Life Cycle Management with LTO

Master concept features support for Long Term Operation is a combination where the equipment and the environment it operates in is one aspects. The ageing process is there and will affect also small parts of the equipment.

The equipment’s life span is not longer than the material inside. Rubber in the shaft the machine will stop the machine unless this rubber sealing is changed and maintained. We know that the life span come to an end and material management in Master concept will assist to check the expire date.

Online and offline

In many maintenance situations there is no network for mobile equipment which creates problems for maintenance technicians. Asset Master operates both online and offline to support offline working conditions.

Tracking changes in the inventory

Financial traceability shows who withdraw equipment from the inventory related to which part of the plant. Also related to what type of workorder that was conducted.

The tracking is automatic over what Purchase Order that added assets to the inventory with built in traceability of what was ordered by whom and when.

Cost units can be charged by the cost for both work and material from the Workorders.

Data and Trend visualization

No matter if the data is simple values or calculated values, we all want to add the data somewhere to be able to visualize them later. It can be a trend of prices over time or equipment that give us a hint of where in its lifecycle it is right now. One or many data value can be stored temperature, voltage and current etc. Each object type with individual range.

We can get feedback if we need to change the equipment due to what the trend show. Generated by the equipment itself or is it something in the environment effecting it.

You store Data on the Object or the physical Individual.

assetMaster

Inventory for Maintenance customers

Our customers using maintenance Master can now manage all their Inventories either traditional Inventories with locations and shelf structures or in combination with service cars having Inventories in each car.

The new material management features with both financial and supply chain forecast support. The organization will be notified when equipment needs to be purchased. All data is based on the planned and forecasted maintenance activities in the preventive maintenance schedules. The system alerts of low levels for each Inventory and the system have a summary overview of all inventories.

One Dashboard for every one

A new set of dashboards are now available for all customers.

Maintenance dashboard

A set of dashboard have been created to assist our customers using maintenance features. Statistics over what type of workorders has been created or which department stand for the % of all workorders. The dashboards are many

Inventory dashboard

Notifications can be shown when Inventories has come to a low level.

Document dashboard

With the Dashboard for documents you will be notified that someone have added a red-lining on one or many documents.